Tooling and Plastic specializes on Plastic Injection Molding and Mold Fabricaction. We offer an integral service to our customers, covering stages from plastic part design, mold design and fabrication, injection molding and parts sub-assembly.

Tooling and Plastic offers SHORT LEAD TIME on end-use plastic parts while providing the highest possible quality to its customers. We deliver parts between 3 to 15 days.

Tooling and Plastic has a highly skilled team of experts on product and tool design, injection molding and tooling engineers that will ensure that your project gets right the first time and on-time. We have state of the art equipment for plastic product development.

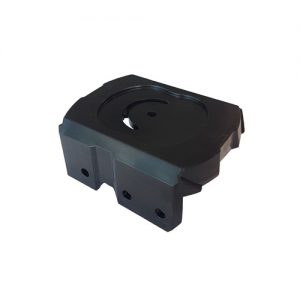

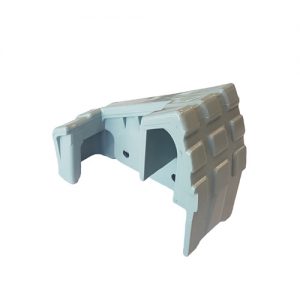

RAPID TOOLING SERVICES

Our Rapid Tooling service is best suited for those who need smaller part quantities, quick turnaround on molds and short lead time.

OUR RAPID TOOLING

MAIN BENEFITS

We quote in 24 hours

Unlimited quotes; there are no restrictions or obligations

Support our customers on plastic part design

Deliver end-use production parts between 3 to 15 days

We inject plastic parts from 20 to 100,000 parts

Choose from different resins and colors

Molds starting at $950 USD

We offer unlimited warranty on molds (mold injected with us)

Quick turnaround time on molds

The following table shows our capabilities for Rapid Tooling services:

| PART DIMENSIONS L x A x E (in) Max | PART WEIGHT (gr) | MOLD PRICES FROM (USD) |

| 2.50 x 2.00 x 1.70 | 50 gr | $950 |

| 4.75 x 4.25 x 3.50 | 180 gr | $1,500 |

| 7.75 x 4.25 x 3.50 | 225 gr | $2,250 |

| 11.75 x 6.50 x 2.75 | 340 gr | $3,500 |

PLASTIC INJECTION MOLDING SERVICES

Our plastic injection molding process has the capability to produce custom prototypes and end-use production parts between 3 to 15 days. We use either aluminum or tool steel molds that offer cost-efficient tooling and accelerated manufacturing cycles, and a stock of a wide range of different engineering thermoplastic resins.

Plastic resin in form of granules is fed via a hopper into a heated barrel, melted using heater bands and the frictional action of a reciprocating screw barrel. The plastic is then injected through a nozzle into a mold cavity where it cools and hardens to the configuration of the cavity. The mold tool is mounted on a moveable platen – when the part has solidified, the platen opens and the part is ejected out using ejector pins. Then, the plastic parts are inspected for defects and dimensions validated according to customer requirements.

Plastic Injection Molding

Our injection molding process has capabilities for single or multiple action molds, single o multi cavity molds, and to process any plastic resin.

Overmolding

Overmolding are two-part injection molding processes where one material is overlaid onto a second part to create a single multi-material component.

Insert Molding

Insert molding are two-part injection molding processes where one material is overlaid onto a second metal insert to create a single multi-material component.

Mold Fabrication

Tooling & Plastic provides Rapid Tooling and Production mold design and fabrication services. We guide our customers along the plastic product design to ensure high quality parts by performing Design For Manufacturing (DFM) practices.

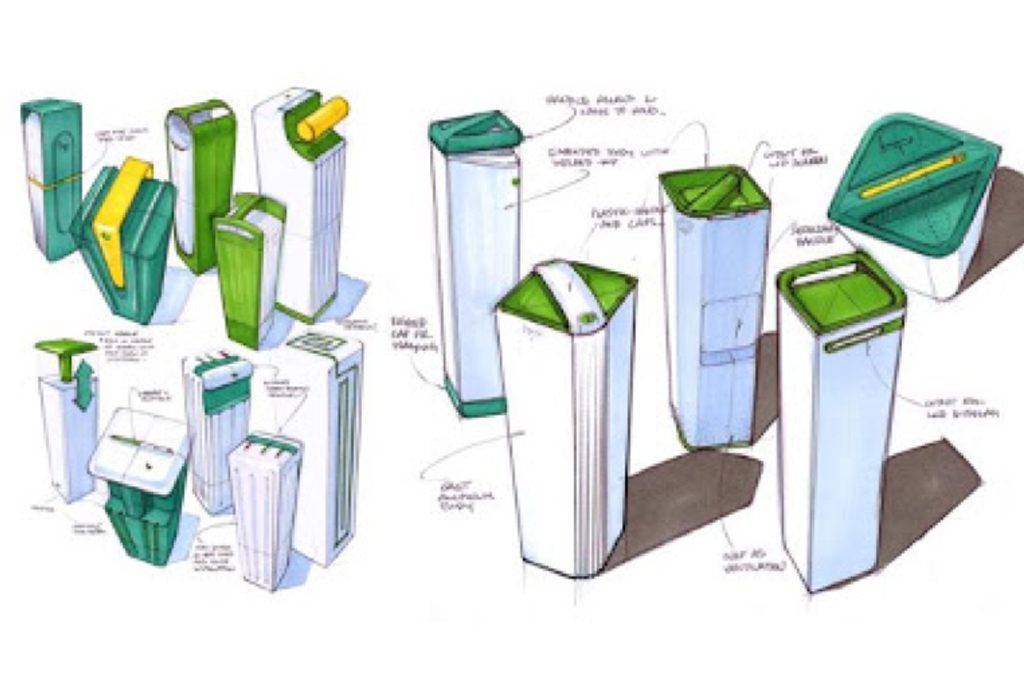

Product Industrial Design

We help you develop your plastic product idea and we offer an integral service to deliver parts.

MATERIALS AND PLASTIC INJECTION MOLDING PROCESS

PLASTIC INJECTION MOLDING PROCESS

EQUIPMENT

Tooling and Plastic has a highly skilled team of experts on product and tool design, injection molding and tooling makers that will ensure that your project gets right the first time and on-time. We have state of the art equipment required to construct molds and to inject parts that perform quality and uniformity.